Gear Pump Size Calculator

Enter value and click on calculate. Result will be displayed.

What is a Gear Pump Size Calculator?

A Gear Pump Size Calculator is a tool used to determine the appropriate size of a gear pump for a specific application. A gear pump is a type of positive displacement pump commonly used to transfer fluids (e.g., oil, fuel, or viscous liquids) in various industrial and automotive systems. The pump size is critical to ensure the required flow rate, pressure, and efficiency.

The key parameters for selecting a gear pump are:

- Flow rate

- System pressure

- Pump speed

- Fluid properties (viscosity and density)

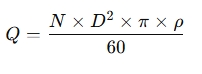

The formula for calculating the flow rate of a gear pump is typically:

where:

- Q= Flow rate (L/min or GPM)

- N= Pump speed (RPM)

- D= Gear diameter (mm or inches)

- ρ= Fluid density (kg/m³ or lb/ft³)

Why Use a Gear Pump Size Calculator?

A calculator is beneficial because:

- It ensures proper pump sizing to meet the required flow and pressure specifications.

- It improves system efficiency, ensuring the pump operates at optimal conditions without overloading or underperforming.

- It reduces energy consumption by selecting the correctly sized pump, preventing unnecessary strain on motors and reducing wear.

- It speeds up the design process by simplifying the calculation of flow rates, pump speeds, and sizes based on system parameters.

How Does a Gear Pump Size Calculator Work?

- Input Parameters: Users enter:

- Desired flow rate (in L/min, GPM, etc.)

- Operating pressure (in bar, psi, etc.)

- Pump speed (in RPM)

- Fluid properties (viscosity, density)

- Gear diameter (if known)

- Computation: The calculator processes the inputs using standard gear pump formulas, adjusting for fluid properties and operating conditions.

- Output Results: It provides the recommended pump size (gear diameter, speed, etc.) for the given flow rate and pressure.

When to Use a Gear Pump Size Calculator?

- In system design to select the correct size gear pump for a hydraulic or lubrication system.

- When upgrading or replacing an existing pump to ensure compatibility with system requirements.

- In fluid handling systems to maintain consistent flow rates under varying pressure conditions.

- In applications where efficiency is critical, such as automotive systems, industrial machinery, and manufacturing equipment.

Did this Calculator help you?

Thanks for the feedback

Search for Calculator

Explore thousands of free calculators trusted by millions worldwide.