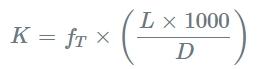

K Value and Pipe Length Calculator

Enter value and click on calculate. Result will be displayed.

fT = Turbulent Friction Factor ---- L = Length

D = Pipe Diameter --- K = K Value

What is a K Value and Pipe Length Calculator?

A K Value and Pipe Length Calculator is a tool used to calculate the pressure drop or head loss in a fluid flowing through a pipe based on the pipe's length and characteristics, as well as the fluid's flow rate and properties. The K value represents the pipe's frictional resistance or flow resistance coefficient, which depends on factors like the pipe's material, diameter, surface roughness, and fittings. The pipe length is the total length of the pipe over which the fluid travels.

Why Use a K Value and Pipe Length Calculator?

You would use a K Value and Pipe Length Calculator for several reasons:

- Pressure Drop Estimation: To determine the pressure drop in a pipe system caused by friction and resistance, which helps in designing efficient systems.

- System Sizing and Design: To size pipes appropriately for fluid transport, ensuring that the pressure drop doesn’t exceed limits that could reduce system efficiency or damage equipment.

- Optimizing Flow Rates: The calculator helps balance the required flow rate with the acceptable pressure drop in systems such as water distribution, HVAC systems, or industrial pipelines.

- Energy Efficiency: Minimizing pressure loss can save energy costs, as pumping or moving fluids with excessive resistance requires more energy.

- Troubleshooting and Maintenance: If there’s a loss of pressure or performance in an existing system, this calculator can help pinpoint whether it’s due to pipe length, K values, or system design.

How Does the K Value and Pipe Length Calculator Work?

A K Value and Pipe Length Calculator typically works by taking the following inputs:

- Pipe Material: Different materials (e.g., steel, PVC, copper) have different frictional resistances.

- Pipe Diameter: The diameter of the pipe, as larger diameters generally reduce frictional losses.

- Pipe Length: The total length of the pipe, as longer pipes result in higher resistance and more pressure drop.

- Flow Rate (Q): The rate at which the fluid flows through the pipe, usually measured in gallons per minute (GPM) or liters per second (L/s).

- Fluid Properties: These include the density and viscosity of the fluid, as thicker and denser fluids tend to have higher frictional losses.

When to Use a K Value and Pipe Length Calculator?

You would use a K Value and Pipe Length Calculator in the following scenarios:

- Designing a Pipe System: When designing plumbing, HVAC, or industrial piping systems, to ensure that the pipe length and diameter are optimal for the required flow rate and acceptable pressure drop.

- Energy Efficiency Analysis: When optimizing systems for energy consumption, especially in fluid transport systems where minimizing pressure loss can result in energy savings.

- Pressure Loss Analysis: If there are concerns about excessive pressure drops in the system, the calculator can help identify whether the pipe length or K value (frictional resistance) is too high.

- Piping System Troubleshooting: If a system isn’t delivering the expected performance, you can use the calculator to check if the pipe length, diameter, or friction factor is contributing to the issue.

- Flow Rate Adjustment: When you need to adjust the flow rate in a system, the calculator helps assess how changes in flow rate will affect the pressure drop and overall system efficiency.

- Maintenance: When assessing the condition of an existing pipeline system, knowing the pipe length and K value helps predict wear and tear effects on the system’s performance.

Search for Calculator

Explore thousands of free calculators trusted by millions worldwide.